Heavy-duty driving wears down parts faster than you think. When your 2018-2023 Jeep Wrangler pulls trailers, tackles snowy roads with a plow, or hauls gear over rocky terrain, your maintenance game has to match the stress your vehicle takes on daily.

Specialized use requires a personal approach. Towing, hauling, or crawling up steep grades in 4WD? Your Jeep Wrangler needs regular inspections, fluid service, and drivetrain care to continue on steadily.

2018-2023 Jeep Wrangler Maintenance Tips

Every heavy-duty mile adds pressure to your Wrangler's internals. Your parts fatigue faster and skipping maintenance starts to cost real money. Owners running Wranglers hard for work or recreation should not rely on standard usage expectations. You have to build a schedule around your driving habits.

Start with a close look at drivetrain components. Front and rear differentials take a beating when torque demands spike. That’s especially true if you’ve upgraded to larger tires or added weight through cargo or aftermarket gear. Transfer cases need clean, high-quality fluid to prevent overheating during 4WD use.

Transmission stress also multiplies under load. If you're towing often or plowing snow in low-speed, high-torque conditions, the factory fluid service interval becomes irrelevant. You need to replace transmission fluid far more often to avoid internal damage.

2018-2023 Jeep Wrangler Heavy-Duty Fluid Service

Heat destroys fluids faster during heavy-duty operation. Once transmission or axle fluid starts breaking down, it loses its protective properties and sludge forms. Chapter 7B of the Haynes Manual covers automatic transmission maintenance and fluid change intervals with a detailed breakdown.

We recommend checking the fluid condition every 15,000 miles and changing it no later than every 30,000 miles for Wranglers under high-load conditions. Neglect here doesn’t just shorten the life of your transmission. It can sideline your vehicle at the worst possible moment.

Axle fluid service is just as important. With heavy hauling or towing, the added stress can create metal particles that contaminate the fluid. Change it more often than the standard interval, especially after a season of snow plowing or hard off-roading.

The transfer case also deserves more frequent attention. It distributes torque between axles and suffers from constant 4WD usage. Fluid breakdown here leads to poor engagement and eventual gear damage. You should inspect and replace transfer case fluid more often if you spend significant time in 4H or 4L modes.

2018-2023 Jeep Wrangler Transmission Care Under Load

Wranglers with automatic transmissions take extra heat during trailer towing or slow technical crawling. Low-speed, high-load use forces the transmission to work harder than it was designed to under factory settings. Consistent towing or off-road use pushes temperatures beyond safe limits even with the factory cooler.

Manual transmissions also experience accelerated wear with heavy-duty use. The clutch and gear synchronizers wear faster under load, especially if you're starting and stopping with a trailer. You’ll want to replace transmission fluid more often than the factory suggests. Don’t wait for the shift quality to degrade.

2018-2023 Jeep Wrangler for Towing and Hauling: What to Look Out for

When you load down your Wrangler or hook up a trailer, you shift how power moves through the chassis. Axle shafts, u-joints, and drive shafts take more strain. Check for slop, wear, or leaks regularly, especially around the seals and joints. You’re looking for play in the u-joints and signs of heat discoloration on the shafts.

Towing and hauling also increase braking demand. Chapter 9 of the manual highlights brake component inspections and replacement criteria. Your brake pads will wear faster and your rotors will overheat more easily. Always inspect the braking system after hauling heavy gear or towing on steep grades. You don’t need the warning light to start looking.

2018-2023 Jeep Wrangler Drivetrain Service Frequency

High-load use impacts every part of the drivetrain. Your maintenance calendar must evolve. Lubricants degrade faster, bearings wear faster, and seals fail sooner. Front and rear differentials, u-joints, wheel hubs, and the transfer case deserve regular service under these conditions.

If you’ve installed larger tires or a lift kit to support your off-road or towing setup, you’re increasing strain even more. A lifted Wrangler sees more wear at ball joints, bushings, and steering linkages.

2018-2023 Jeep Wrangler Off-Road Powertrain Survival

Off-road work puts torque demands at their highest. That includes crawling in 4L, climbing inclines, crossing rivers, or navigating loose terrain with locked differentials. Powertrain components like axles, driveshafts, and differentials hit their limits faster off-road than on pavement.

You won’t always notice the wear immediately, but it builds with every trail run. It’s worth reviewing after deep water crossings or dusty runs that could clog sensors and exhaust components.

Your battery and alternator face higher demand if you use winches, aftermarket lighting, or refrigeration systems on long off-grid trips. Check terminals, output, and voltage drop regularly to avoid a dead start in the backcountry.

Long-Term Durability Starts with Smarter Service

Every towing trip or snow plow job pushes your Wrangler further away from what the owner’s manual expects. Regular inspections, fluid replacements, and focused maintenance prevent expensive downtime and protect your investment.

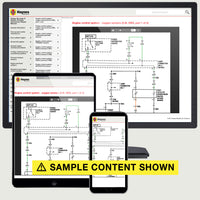

The Haynes Manual for the 2018-2023 Jeep Wrangler gives you the detailed information you need to manage these demands. Chapter after chapter breaks down what to check, how often to replace core components, and how to service your Wrangler the right way based on real-world use.

To stay ahead of wear and drive confidently through the toughest jobs, get your Haynes Manual for the 2018-2023 Jeep Wrangler today. It’s your best resource for real-world repair strategies and drivetrain care for heavy-duty drivers.